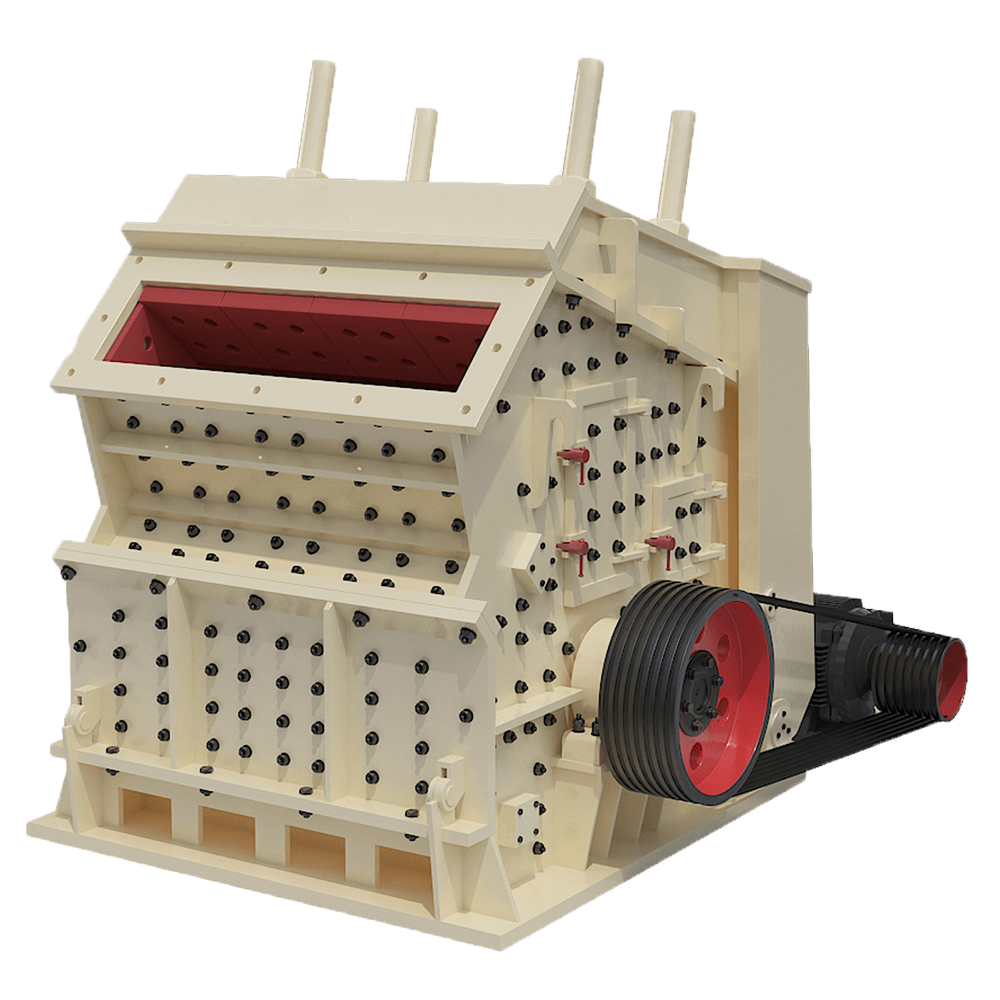

Powerful Crushing Solutions Await: Discover the current Impact Crusher for Sale

Powerful Crushing Solutions Await: Discover the current Impact Crusher for Sale

Blog Article

Revolutionize Your Recycling Operations With an Effect Crusher

One such remedy that has gained substantial interest is the influence crusher. Exactly how exactly does an influence crusher work, and what are the advantages it can offer? In this discussion, we will certainly explore the internal workings of an effect crusher, the types of products it can process, and give ideas for optimizing its effectiveness.

How an Effect Crusher Works

An effect crusher runs by utilizing a high-speed rotor and a crushing chamber to properly break down materials right into smaller sized, more manageable sizes. The fragmented product then enters the crushing chamber, where it is additional lowered in size by the influence pressures generated by the rotating rotor.

Among the essential benefits of an influence crusher is its capacity to generate an uniform fragment form. Unlike various other squashing approaches, such as jaw crushers, which tend to generate even more elongated fragments, influence crushers create cubical-shaped bits. This is because of the high-speed effect pressures produced by the blades, which successfully ruin the material and create a more constant product.

Moreover, effect crushers are extremely versatile machines that can deal with a broad array of products. From friable and soft materials like limestone to hard and rough materials like granite, impact crushers can effectively refine numerous kinds of products. This makes them ideal for usage in reusing operations, where various types of products require to be processed and changed right into multiple-use items.

Benefits of Using an Influence Crusher

With its ability to produce a consistent bit shape and take care of a large range of products, the impact crusher supplies a wide variety of benefits in numerous reusing operations. Among the crucial advantages is its performance in decreasing the dimension of materials. The influence crusher utilizes a high-speed influence pressure to break down products, leading to an extra effective and cost-effective process contrasted to various other crushers. Furthermore, the impact crusher has a reduced operating expense as it calls for less upkeep and has a much longer life expectancy.

One more advantage of making use of an impact crusher is its convenience. It can handle various types of materials, including demolition, asphalt, and concrete waste. This makes it suitable for recycling operations where various sorts of materials are come across. Moreover, the impact crusher can generate a consistent fragment shape, which is vital in recycling applications. By creating constant fragment sizes, the effect crusher guarantees that the recycled materials can be made use of for numerous objectives, such as roadway building and construction or as aggregate in new concrete.

Types of Products That Can Be Refined

The effect crusher is qualified of processing a broad array of materials, making it extremely versatile in recycling procedures. One of the primary products that can be processed by an influence crusher is concrete. The ability to refine such a wide array of materials makes the effect crusher a crucial tool in recycling operations, allowing the recuperation and reuse of valuable resources while lowering waste and environmental effect.

Tips for Making The Most Of Efficiency With an Impact Crusher

To maximize the performance of an effect crusher and achieve optimal effectiveness, drivers should execute numerous essential approaches. Operators must also make sure that the influence crusher is correctly oiled to lower rubbing and prevent unnecessary wear and tear.

An additional essential idea is to adjust the crusher setups according to the certain needs of the material being processed. This can be done by keeping track of the feed dimension, the speed of the blades, and the void between the effect plates. By fine-tuning these setups, drivers can make certain that the crusher is running at its optimal capability and creating the wanted result size.

Furthermore, operators must carefully choose the proper feed product for the impact crusher. This includes recognizing the characteristics of the material and its impact on the crusher's performance. It is important to avoid feeding exceedingly tough or oversized products that may cause damage to the equipment or cause inefficient crushing.

Finally, drivers need to consistently keep an eye on the performance of the impact crusher and make modifications as required. This Get More Information can be done by examining the item high quality, production price, and power usage. By constantly examining and enhancing the crusher's efficiency, operators can maximize efficiency and lower downtime.

Ecological Impact of Using an Influence Crusher

Frequently checking and enhancing the performance of an effect crusher not only optimizes effectiveness and decreases downtime, but it additionally enables operators to assess and alleviate the environmental impact of making use of the crusher. The environmental impact of making use of an effect crusher can be substantial, particularly if proper actions are not taken to minimize it. Among the major worries is the emission of dirt and particulate issue during the crushing process. These fragments can add to air contamination and can have dangerous impacts on human wellness and the bordering ecosystem.

To mitigate this impact, operators can execute different procedures. In addition, normal upkeep and assessment of the crusher can aid check this identify and deal with any issues that may lead to increased dust discharges.

An additional ecological issue is the sound produced by the influence crusher. They can likewise set up squashing operations during times when noise influence is decreased, such as throughout daytime hours when sound from surrounding activities is higher.

Verdict

To conclude, integrating an impact crusher into recycling procedures can reinvent the process by effectively improving and crushing numerous materials performance. The benefits of making use of an effect crusher consist of decreased waste quantities, raised production rates, and enhanced item quality. By adhering to tips for optimizing effectiveness and considering the ecological influence, recycling operations can greatly their website take advantage of using an influence crusher.

The impact crusher utilizes a high-speed influence force to break down materials, resulting in a much more economical and reliable process compared to other crushers. The capacity to refine such a broad variety of products makes the influence crusher a crucial tool in recycling procedures, making it possible for the recuperation and reuse of valuable resources while minimizing waste and environmental impact.

On a regular basis monitoring and enhancing the performance of an impact crusher not just maximizes performance and minimizes downtime, yet it likewise allows drivers to analyze and mitigate the ecological effect of making use of the crusher. The environmental effect of using an influence crusher can be substantial, especially if appropriate steps are not taken to reduce it. By complying with pointers for taking full advantage of effectiveness and taking into consideration the ecological influence, recycling procedures can significantly benefit from the use of an effect crusher.

Report this page